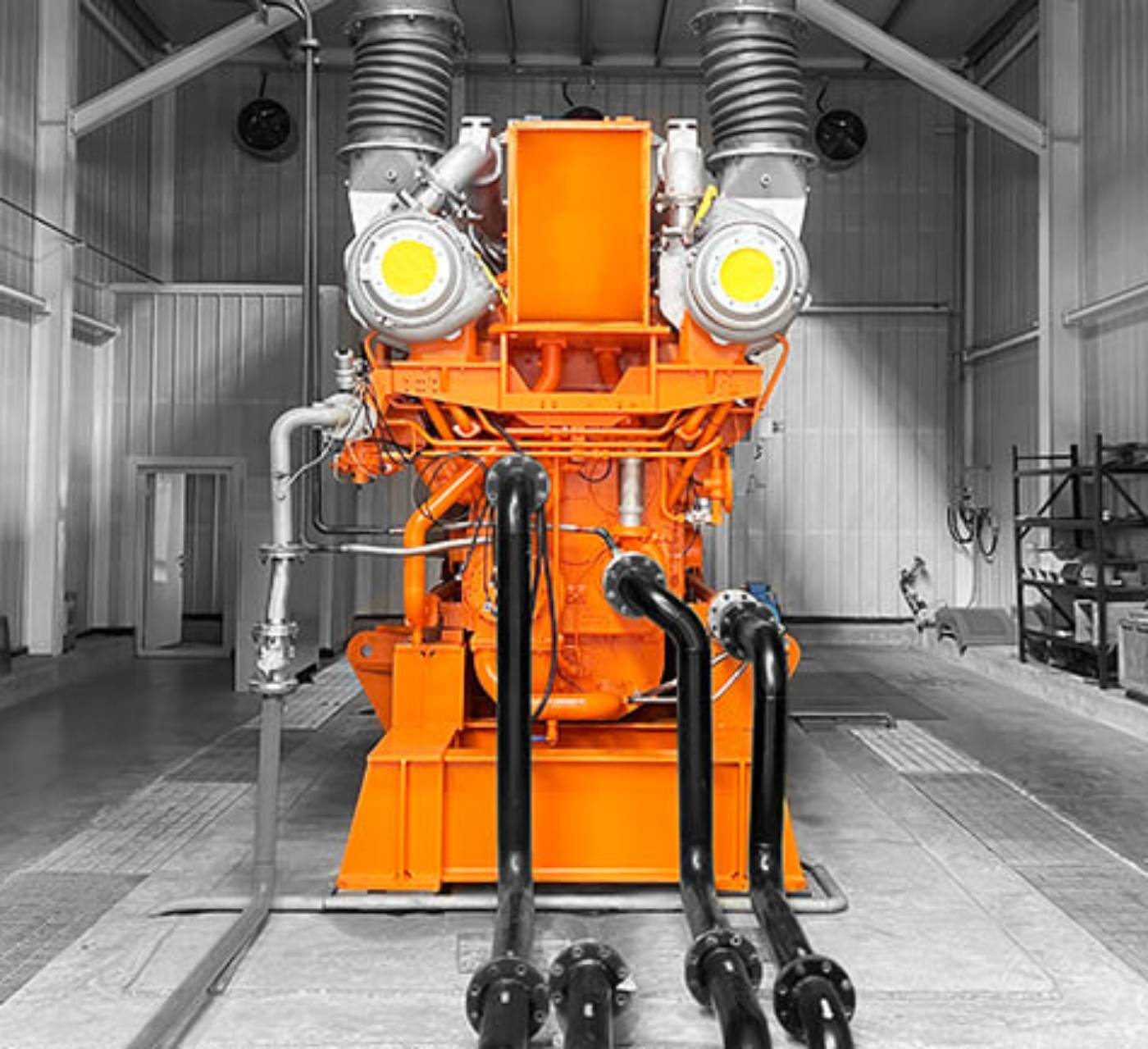

The ED1012/ED1020 gas engine systems

represent a synergy of advanced Western technologies, a robust manufacturing base in China, and minimal production lead times.

ED1012/ED1020 engines meet global quality standards, are highly adaptable, and are designed to meet the demand for gas

engine systems across various industries and markets. The control system for the units was developed in collaboration with Shanghai Aerospace General Aviation.

The product line includes units with an electric output ranging from 2250 to 3000 kW.

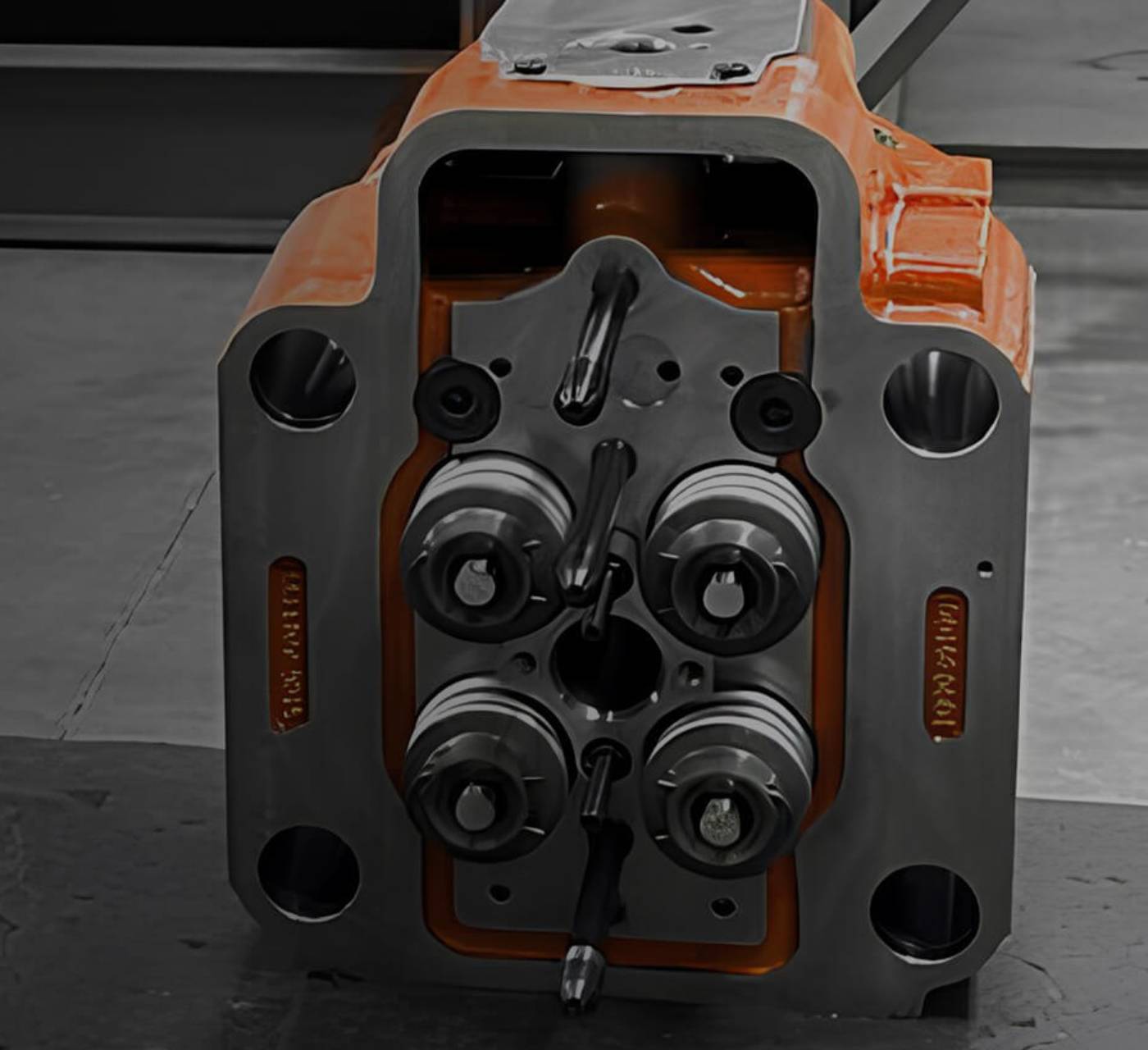

Engine Specifications

Efficient, professional, and high-quality performance

2300KWe 10.5kv/50Hz

No. of cylinders: V12

Displacement: L 214

L×W×H mm: 4739×2230×3179

Engine dry weight: kg 23900

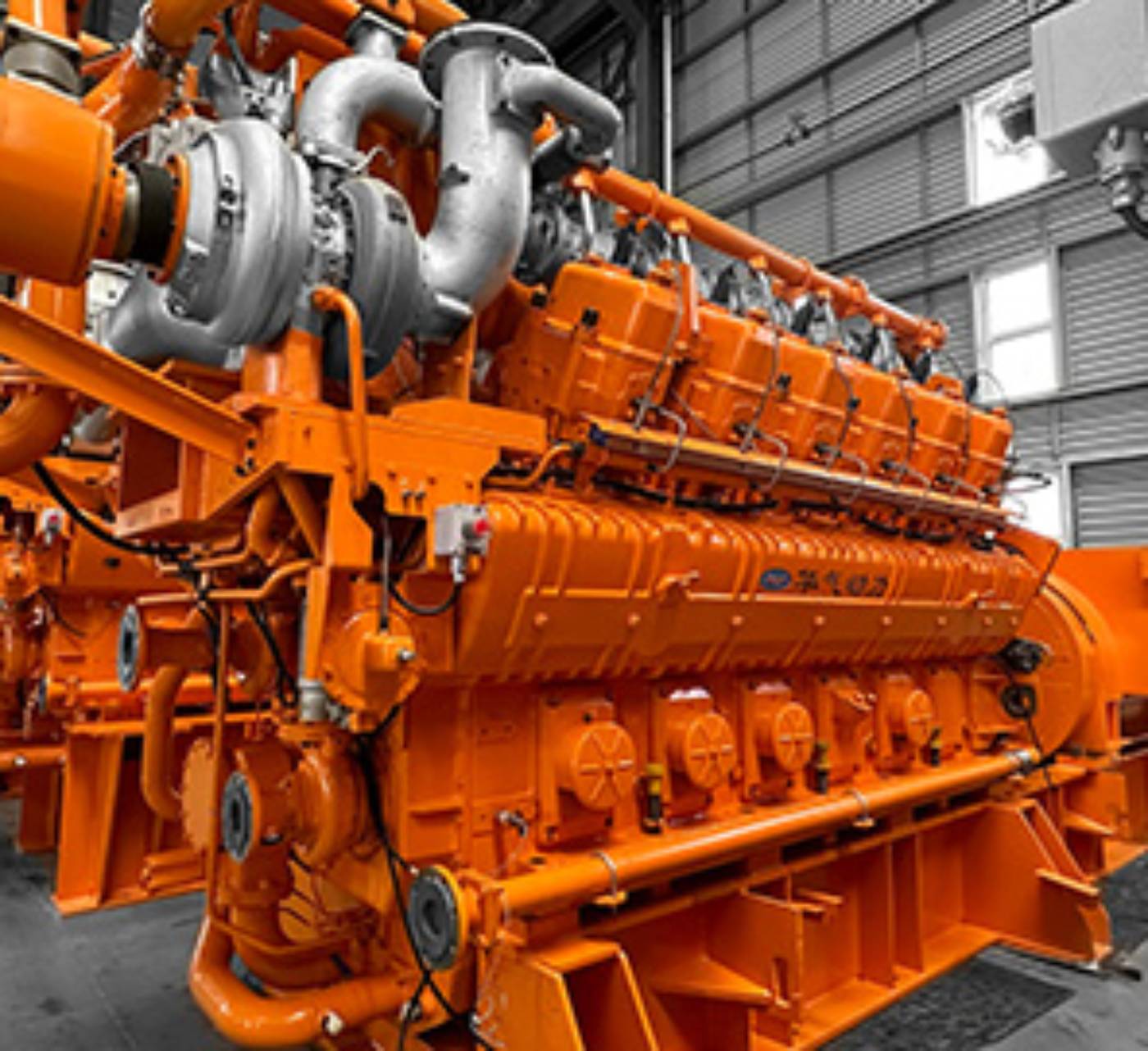

3000KWe 10.5kv/50Hz

No. of cylinders: V16

Displacement: L 285

L×W×H mm: 5659×2266×3179

Engine dry weight: kg 30800

Lifecycle Contracts

Long-term service contracts are the optimal choice for economic planning and efficient maintenance of gas engines.

Signing such a contract ensures the availability of necessary spare parts at the time of scheduled maintenance and repairs, reduces lifecycle costs, and enhances the reliability of the equipment.